MTBF – mean time between failure (Mean Time Between Failure)This parameter is often misinterpreted. MTBF of the power supply may be 700,000 hours, i.e. almost 80 years. However, it does not mean that the power supply will operate failure-free for such a long time.

|

The methods to calculate MTBF were introduced by the US Army in 1965 with the publication of MIL-HDBK-217 model. The model included the failure rates for different electronic components, i.e. capacitors, resistors and transistors and the methods to calculate the failure rate. It was supposed to standardise the reliability evaluation methods for electronic and military equipment.

|

Apart from MIL-HDBK-217 models, other models to calculate the MTBF are available in the specifications for electronic devices. The models use different algorithms to calculate reliability. Example methods: HRD5, Telcordia, RBD, Markow model, FMEA/FMECA, failure tree, HALT.

|

With a known MTBF time we can calculate the probability of the device failure before the MTBF elapses. It is a very useful information that allows to evaluate the overall reliability of a system. The rule is simple: the higher the MTBF, the more reliable the device.

|

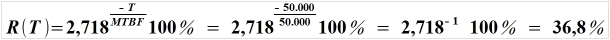

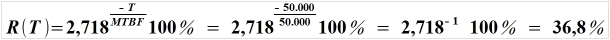

MTBF is a time, after which the reliability of the device drops to 36.8%.

|

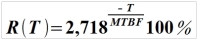

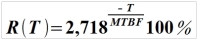

How is that possible? The calculation uses an equation for reliability. |

| R(T) – reliability expressed as percentages in relation to device operation time T – device operation time MTBF – mean time between failure 2,718 – Euler number (denoted as the letter "e") |

|

In words: 2,718 to the negative power of operation time divided by MTBF.

|

Let us calculate the failure rate of a device with MTBF of 50,000 hours after 50,000 hours of operation.

|

The device with MTBF = 50,000 hours has a reliability of 36.8% after 50,000 hours of operation. In other words, after 50,000 hours, the probability is that for every 100 devices approx. 37 will still be in operation and 63 will fail.

|

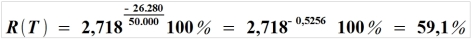

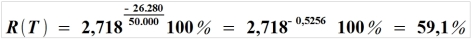

Let us verify the probability of a failure within 3 years for two power supplies with different MTBF.

|

1. MTBF = 50,000 hours, 3 years = 3 years x 24 hours x 365 days = 26,280 hours:

|

The results show the probability that after 3 years 59.1% of the power supplies will still be in operation (e.g. for every 100 devices, approx. 59 devices will still be in operation and 41 will fail).

|

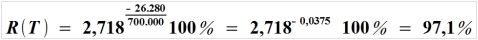

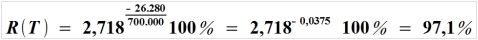

2. MTBF = 70,000 hours, 3 years = 3 years x 24 hours x 365 days = 26,280 hours:

|

This case shows the probability that after 3 years 97.1% of the power supplies will still be in operation (e.g. for every 100 devices, approx. 97 will still be in operation and 3 will fail).

|

Most often, MTBF is determined by the manufacturer in relation to the device operation at 25°C. For operation at higher temperatures, the increase in temperature by 10°C reduces the MTBF by half. Why does MTBF differ for different devices? The difference is usually due to the quality of components and the degree of complexity. Not all manufacturers include this parameter in the product specification.

|

|